Capabilities

We take great pride in our capabilities at CESSCO Fabrication & Engineering Ltd.

Our history in the pressure vessel fabrication industry dates back to 1948, and we have been in the metal stress relieving business since 1965. With decades of experience working on the largest, heaviest, and most complex pressure vessels in North America, our reputation for design integrity, quality workmanship, and customer service remains unsurpassed.

Being located in the heart of Alberta’s nine-meter high-load corridor allows us to transport our pressure vessels and components to our clients throughout Canada and the United States of America, assisting us with delivering results. We have confidence in our capacity to provide custom fabrication with seamless project management.

Our capabilities for services and packaging include hydro testing, non destructive examination, painting and coating, insulation, post weld heat treatment, heat tracing, fire proofing, skid design, fabrication and equipment mounting, pressure piping fabrication and skid installation, ladder and platform design and fabrication, instruments and valves installation, electrical installation, insulation, and any other service required by your project needs.

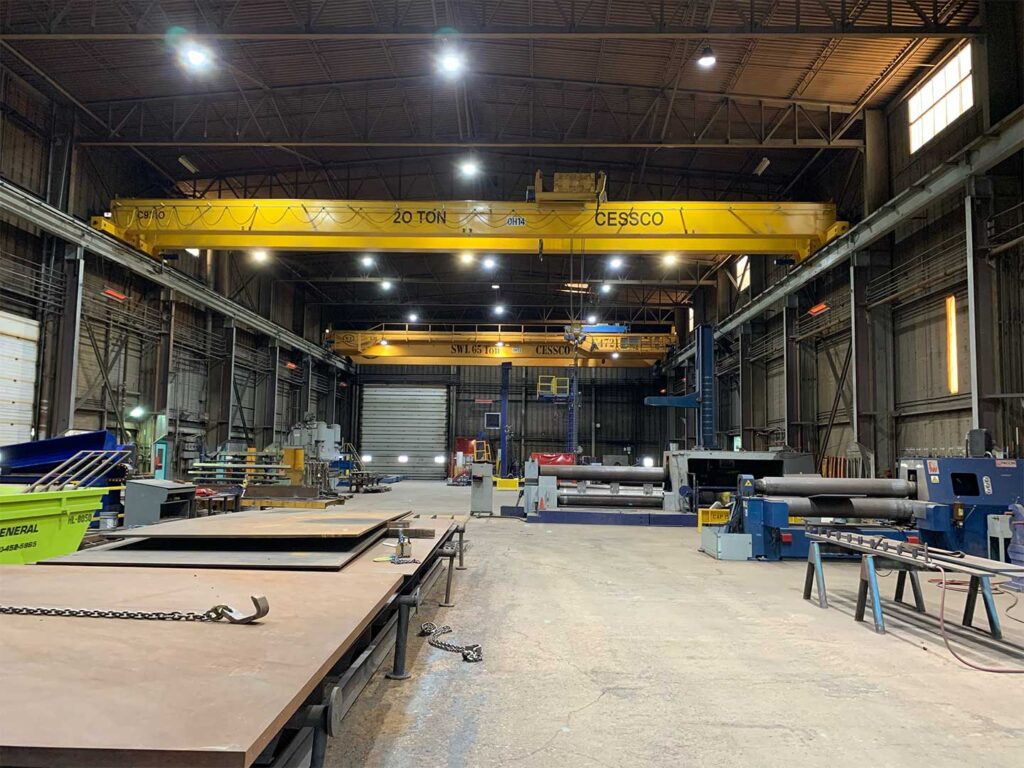

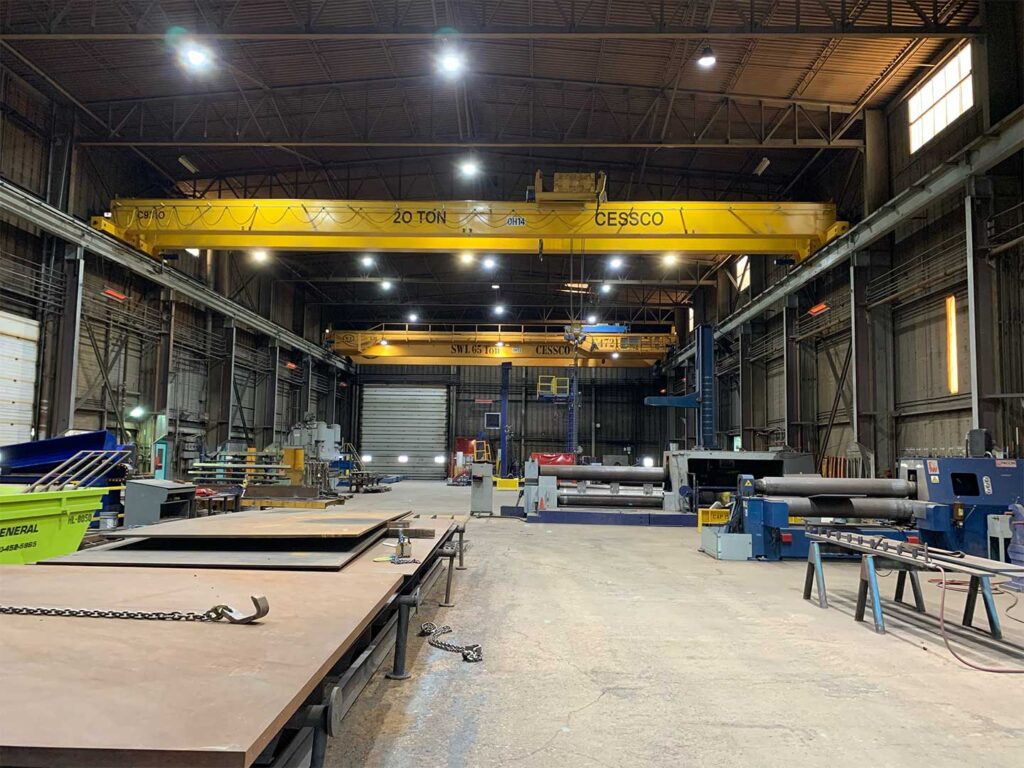

Capacity

While we specialize in pressure vessels that range up to 36 feet in diameter, 400 feet in length, and 750 tons in weight, we have the capacity to take on a project of any size.

On our properties, we have more than 150,000 square feet of shop space featuring assembly shops, a preparation shop, a machine shop, a paint tent, and single shop lifting capacity of 210 tons. Additionally, we have three heat treating furnaces, including a modular one that is 36 feet wide, 36 feet tall, and can be extended to over 200 feet long, making it one of the largest ovens in Western Canada.

Custom Fabrication

CESSCO Fabrication & Engineering Ltd. tackles the most challenging and unique pressure vessel fabrication projects with innovative solutions.

In more than seven decades, we have developed over 400 welding procedures, built hundreds of the largest pressure vessels you’ll ever see transported all throughout Western Canada, and collected a comprehensive inventory of equipment, including various CNC equipment for cutting, rolling and machining, ensuring we are equipped to meet and exceed client expectations. With our extensive experience in cutting, plate rolling, and beveling for customers that produce tanks and smaller pressure vessels for process applications, we provide custom machining of fabricated products as well as restoration and repair for large and heavy equipment. Furthermore, we work with various materials such as carbon steel, stainless steel, chrome moly and other alloys, and nickel with thicknesses up to eight inches.

Project Management

As a metal fabrication company recognized as being a cost-effective solutions provider, we offer consistent project management for our clients. Our experienced project managers, supported by our subject matter experts, have decades of experience managing complex and high-profile projects, ensuring regular communications and project updates as they are paramount to the success of all our projects.

We endeavor to complete our projects on time and on budget. With our thorough approach, we adhere to the highest industry standards and regulatory requirements throughout every stage of the process. We are meticulous in our execution of each project, and our high-quality services have been a mainstay for a range of industries including oil and gas, petrochemical, pulp and paper, mining, fertilizer, cement, and new green technologies.